Yes, it's cool isn't it?

We've got Slice's award-winning box cutters with ergonomic J-hook

handles, pen cutters and the Mini Cutter stocked up at Scrap-n-Crop.com.

Having won numerous design awards and featured in many gadgets blog, the Slice is a top choice both at home and at offices/ manufacturing lines as it provides users safer cutting and ergonomic experience which in turns reduces injuries and down time.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

click HERE to buy Slice ceramic cutters from Scrap-n-Crop.com

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

so, what's slice ceramics all about?.

Slice ceramics

are not the fragile ceramics of popular imagination. They’re actually part of a

more recent category of material known variously as advanced ceramics, fine

ceramics, or engineered ceramics. The material is composed of 100 percent

zirconium oxide. This material, developed through the advances in ceramic

research of the 1950s, has many useful properties.

A Versatile Material

Zirconium oxide

has many advantages over steel, especially for industrial applications. Unlike

metal, a zirconium oxide utility blade is chemically inert. This means no

chance of chemical reactions while you cut, as well as a strong defense against

harmful bacteria. Ceramic never rusts, which means it doesn’t require the same

oils and lubricants used on metal blades to prevent premature rusting.

Industries as

varied as pulp and paper and aerospace benefit from the use of engineered

ceramic utility blades because of these inherent properties:

· Non-magnetic

· Anti-static

· Non-conductive

· Non-sparking

· Safe up to 1600

degrees Celsius

· Chemically inert and

non-contaminating

· Non-reactive:

impervious to acids and salt

· Non-porous and

chemically resistant

· Oil and lubricant

free

· Never rusts

Hard as Nails (Harder, Actually)

When customers

used to metal blades try Slice tools for the first time, they’re comparing two

very different cutting materials. There are important manufacturing differences

between a Slice ceramic blade vs steel, due to the different properties of

these materials. The primary difference is hardness.

What Does Slice Mean by Finger Friendly?

Finger friendly simply means that Slice blades are safer to

touch and handle than typical steel blades. You can pick up Slice replacement

blades without fear of accidental injury. Compared with typical blades, for

example, our utility blades are unlikely to cut you because they require much

more force to do so. As shown below, you can run a Slice blade over a balloon’s

surface and the balloon will remain intact. That’s simply not the case for

steel blades.

wow that video is amazing!

So if Slice Blades Cut Other Materials Effectively, How Do They Resist Skin?

Slice engineers

first looked at why metal blades pierce the skin so easily. Not only are their

edges overly sharp, but the blade itself is quite narrow. This means it

requires little force to pierce the skin.

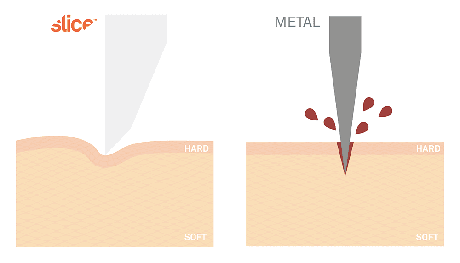

Image: The initial cutting zone is defined as the part of a blade’s

edge that does the actual cutting. This zone is a result of the angle used to

grind the blade. In a metal blade, the smaller angle creates a longer and

sharper cutting zone, making users much more vulnerable to lacerations. Slice

uses a patented double grind that shortens the cutting zone significantly. This

creates an effective cutting edge that doesn’t endanger the user.

Finally, we took into account the properties of skin, which is harder on

the surface, but pliable as a whole. Our grind dissipates the pressure on skin,

making it harder to penetrate.

Image: Skin is hard on outside and soft on the inside. Slice engineers took

this into account when designing our blades. Our wider angle displaces the

force of the blade against skin’s tougher, fleshy outer layer. In contrast,

with nowhere for the exterior force to go but in, narrow metal blades easily

pierce skin.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

click HERE to buy Slice ceramic cutters from Scrap-n-Crop.com

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

No comments:

Post a Comment